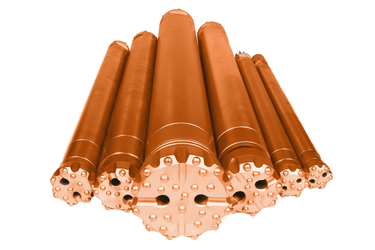

DTH Hammers & Hammer Bits

A down-hole hammer is a percussion hammer drill. In this type of hammer the piston applying repeated percussive pressure is in direct contact with the bit. As the name implies, this hammer works "down the hole". The hammer and the bit are located at the end of the drill string. One of the main advantages of the DTH hammer is that the drilling rate is not affected very much by the length or depth of the hole. DTH Hammers are well suited for drilling into medium hard to hard rock. They are especially well suited for drilling into fractured rock. They are extensively used in mining, quarrying, civil engineering and water well drilling industries.

Rocksmith offers top quality DTH hammers and bits. Our products have been tried and tested in the harshest of rock conditions. Our bits utilize quality hardened steel alloy for the bit body and premium quality tungsten carbide button inserts. Our products are recognized for having exceptional durability resulting in a very loyal and satisfied clientele.

Rocksmith provides hammers and bits with most popular shanks. We also specialize in supplying spares for individual hammer components.

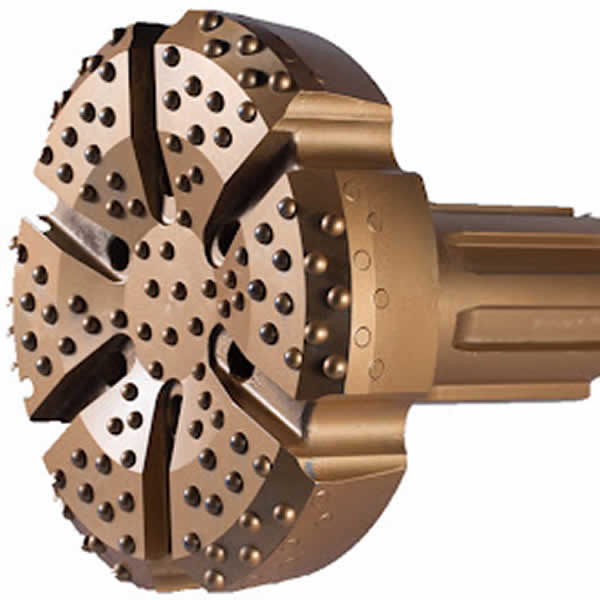

To help ease the selection process we have categorized our DTH hammers based on hammer dimensions and our bits based on shank designation, bit diameter, bit face configuration, and carbide design.

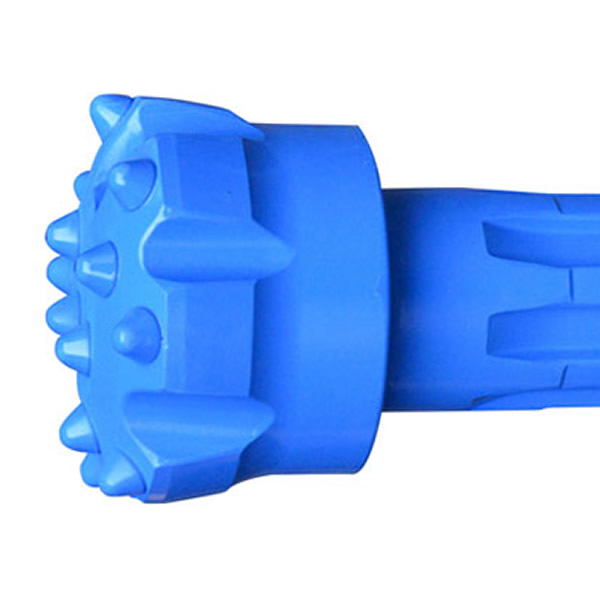

Rocksmith offers DTH bits having concave, flat face and convex bit face configuration.

1800 999 893

1800 999 893

view DTH Hammers and Bits catalogue

view DTH Hammers and Bits catalogue